Our Location

UNIT 1406A, 14/F, THE BELGIAN BANK BUILDING, NOS. 721-725 NATHAN ROAD, MONG KOK HONG KONG

In the world of automated access control, the motor is the “heart” of the barrier gate. Choosing between a Brushed DC (BDC) and a Brushless DC (BLDC) motor can significantly impact the system’s longevity, maintenance costs, and control flexibility.

While the industry is shifting toward brushless technology, both types serve specific market needs. Here is a technical breakdown of their differences, working principles, and why certain professionals still prefer one over the other.

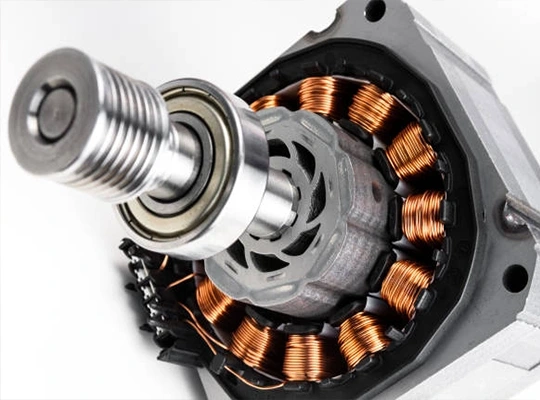

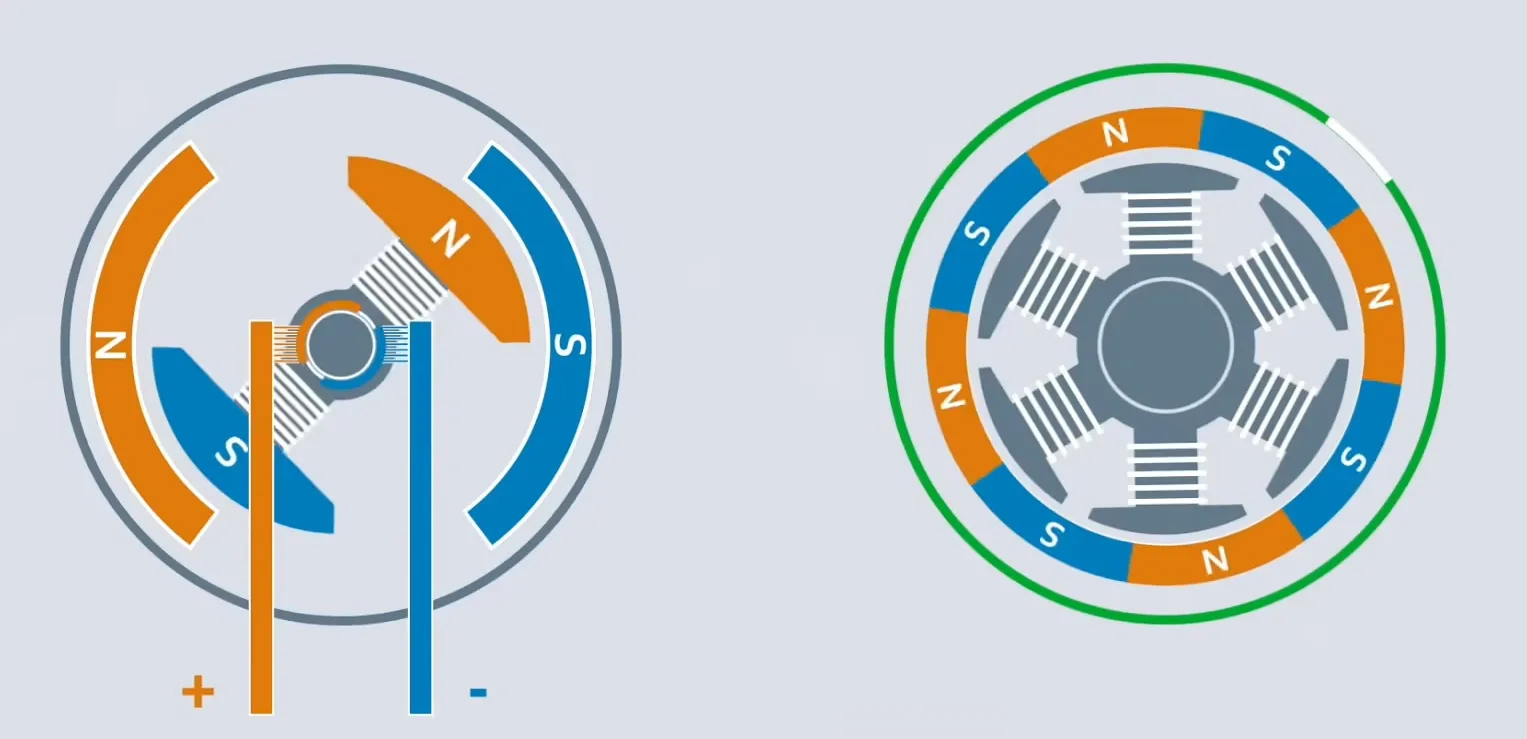

A Brushed DC motor consists of four basic parts: the stator (permanent magnets), the rotor (armature coils), a commutator, and carbon brushes.

The brushes make physical contact with the commutator to deliver electrical current to the spinning coils. As the rotor turns, the brushes flip the magnetic polarity, keeping the motor in motion.

Interestingly, some high-end engineering firms and gate manufacturers still opt for brushed motors without controllers.

As the name suggests, BLDC motors eliminate the brushes. The magnets are placed on the rotor, while the copper coils are fixed on the stator.

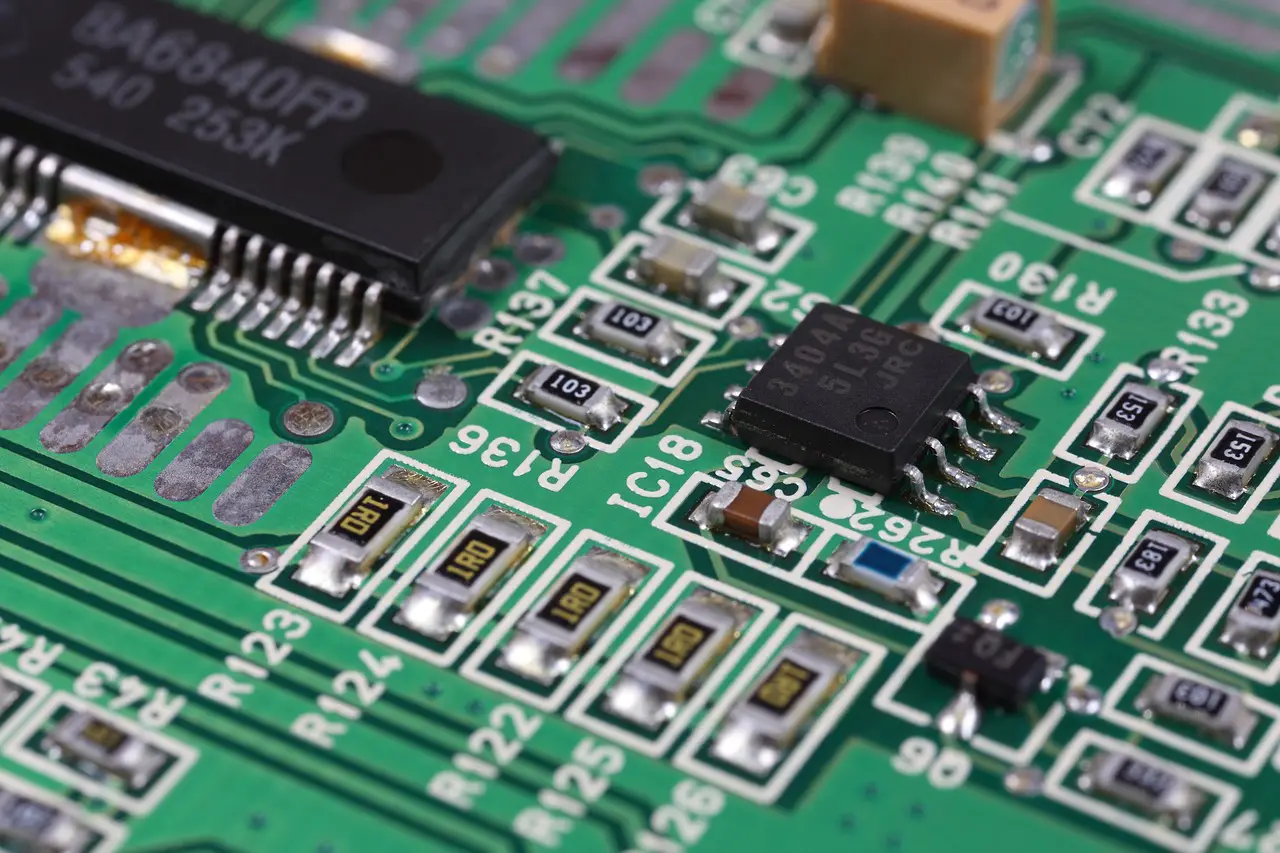

Because there is no physical contact to flip the polarity, the “switching” is done electronically by an External Controller (Electronic Speed Controller – ESC). This controller uses sensors (usually Hall effect sensors) to track the rotor’s position and pulse electricity to the coils at the perfect micro-second.

| Feature | Brushed DC (BDC) | Brushless DC (BLDC) |

| Commutation | Mechanical (Brushes/Commutator) | Electronic (Controller) |

| Maintenance | High (Brushes wear out) | Minimal (No friction parts) |

| Lifespan | Moderate | Very High |

| Friction/Heat | Significant | Minimal |

| Control Requirement | Simple (Direct DC Power) | High (Requires dedicated ESC) |

| Market Trend | Legacy/Specialized | Mainstream/Modern |

For most property management and standard commercial projects, BLDC is the superior choice. The reduction in friction translates directly to fewer service calls and a higher “Mean Time Between Failures” (MTBF). For high-traffic areas like toll booths or busy parking lots, the reliability of BLDC is essential.

If you are an engineering company with your own proprietary control hardware and require full ownership over the software logic of the gate, a high-quality Brushed DC motor provides a reliable, “blank slate” mechanical component. It allows you to implement unique functions without the compatibility hurdles often found in integrated BLDC systems.