Since 1999, ACCESS TECH has specialized in manufacturing anti-rust barrier gate built to perform in the most demanding environments. Our multi-stage surface treatment process combines phosphating, electrophoretic coating, and electrostatic powder coating to deliver unmatched corrosion resistance, mechanical strength, and aesthetic longevity.

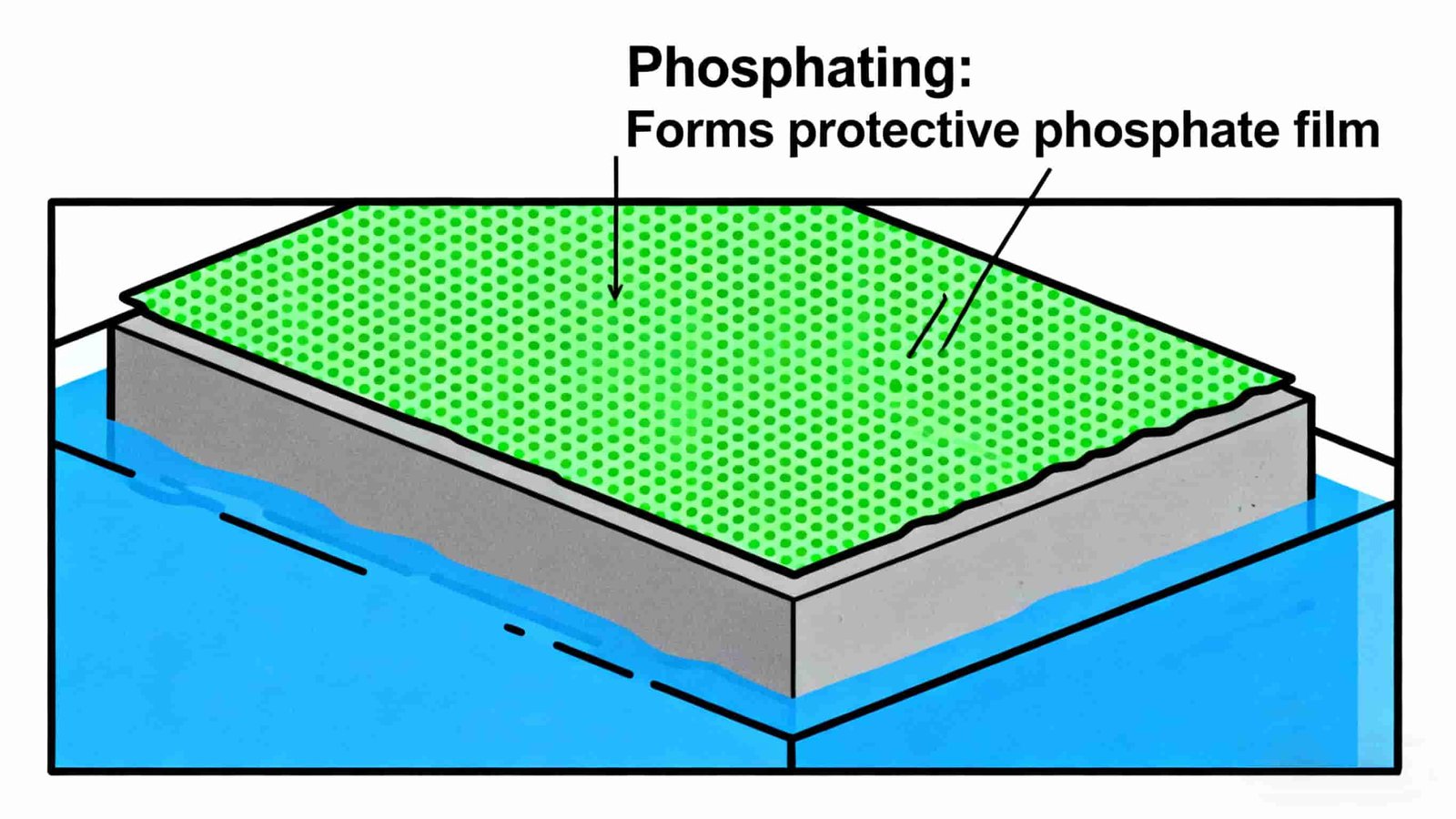

Stage 1: Phosphating – The Critical Foundation

The process begins with phosphating, a chemical surface treatment that serves two essential functions:

- Deep Cleaning: Removes all impurities, including oils, rust, mill scale, and other contaminants, from the metal cabinet surface.

- Surface Activation: Creates a microcrystalline phosphate layer that significantly enhances the adhesion of subsequent coatings and provides preliminary corrosion resistance.

Stage 2: Electrophoretic Coating – Total Coverage with Molecular Anchoring

Following phosphating, the cabinet undergoes electrophoretic coating (E-coating), which offers far more than just surface-level protection:

- Molecular Anchoring: The paint particles penetrate into microscopic pores on the metal surface during the electrochemical process, forming a powerful “anchor” effect that results in adhesion far superior to conventional spray painting.

- Exceptional Hardness: The cured e-coat layer is highly resistant to minor abrasion, impact, and handling scratches, maintaining integrity throughout the gate’s operational life.

- Uniform Protection: Ensures complete coverage—including edges, welds, and internal structures—leaving no room for corrosion to start.

Stage 3: Electrostatic Powder Coating + High-Temperature Curing – The Final Shield

After e-coating, a layer of resin-based powder is applied using electrostatic spraying. This stage offers several key advantages:

- Eco-Friendly & Efficient: The process is free of volatile organic compounds (VOCs), making it environmentally responsible.

- Excellent Adhesion & Uniform Color: Electrostatic attraction ensures the powder wraps the cabinet evenly, resulting in a consistent, high-quality finish available in custom colors.

- High-Temperature Curing: Once applied, the cabinet enters a high-temperature oven. The powder melts, flows, and chemically cross-links into a durable, smooth film. After cooling, the finish exhibits extreme adhesion and impact resistance—far outperforming conventional wet paints.

Why This Multi-Stage Coating System Is So Effective

Together, these stages form a synergistic defense:

- Phosphating cleans and prepares the surface.

- E-coating seals the metal with deep-binding, rust-inhibiting protection.

- Powder coating adds a tough, flexible, and colorful outer shell that withstands physical and environmental stress.

Stainless Steel Options Available

For highly corrosive settings, we also offer cabinets in 304 or 316 stainless steel—ideal for coastal and industrial zones.

Why Choose ACCESS TECH?

- ✅ Over 25 years of manufacturing expertise

- ✅ Complete in-house surface treatment line

- ✅ Custom color and finish options

- ✅ Designed for harsh and high-traffic environments

Conclusion

ACCESS TECH’s anti-rust barrier gate are engineered with a coating system that works on both a molecular and mechanical level. From phosphating and e-coating to electrostatic powder coating, each step is designed to maximize adhesion, hardness, and corrosion resistance—ensuring your access control solution remains reliable and visually professional for years to come.

[…] face harsh conditions: rain, humidity, and constant use. That’s why our cabinets undergo advanced multi-step treatments. These include anti-corrosion coatings and weather sealing to eliminate rust and degradation, […]